Top labeler HERMA 452E: precision and speed at the same time

452E - No compromise on precision and performance

- The 452E is designed for rectangular or cylindrical structurally and dimensionally stable products with measurements of 50 x 50 x 15 mm - 100 x 100 x 150 mm (L x B x H)

- Ideally suited to the requirements of many Fast Moving Consumer Goods (FMCG), such as cosmetics, care and household products - as well as for the labeling of snus

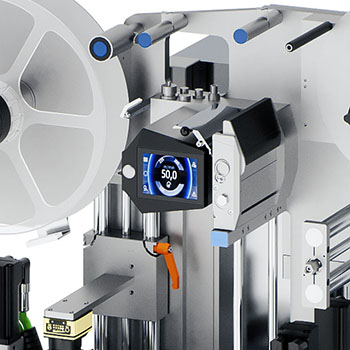

- Reproducible labeling results can be achieved at any time with the digital position indicators and the integrated high-performance applicator HERMA 500 - even with high speeds of up to 250 products per minute

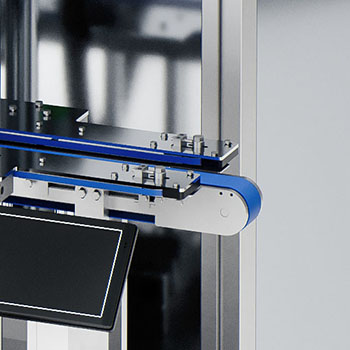

- Side guides can be adjusted quickly and without tools to various product dimensions at any time

- Optionally available with the new self-adjusting system for tracking the label position

The 452E stands for reliability, precision and speed

All these attributes are provided by the machine’s generous equipment. Among other things, it offers easy access for adjustments, the innovative HERMA 500, a control system for label presence check and a control panel for managing all formats. With the top labeler 452E you are no longer faced with a choice between labeling precision and speed – it delivers both at the same time.

This is how the optional self-adjusting system works:

A special camera system first inspects the products after labeling. In addition to the presence of the labels, it also checks their position on the products. The data collected regarding the label position are subsequently used for the fully-automated adjustment of the next labeling. The tracking system can intervene to make corrections in two ways: It achieves the adaptation in the running direction of the products via the start delay, while in a lateral direction, it can readjust the two side belts that guide the products. This fully-automated adaptation enables the labeling machine to apply round or rectangular labels to product surfaces, while keeping labeling tolerances at a very low level. Even an edge trim of the labels, which is not 100 percent, can be compensated by individual positioning of the cylindrical products. Products with a missing, incorrectly positioned or wrong label are registered and then transported into a reject box with a compressed air blast – a checking sensor monitors that the products leave the machine.

Best results & useful options

|

|

Thanks to the integrated HERMA 500, high throughput – even during continuous operation – and absolutely precise label application are guaranteed. |

|

|

Equipped with a control panel, PLC and intuitive user interface, the operator has all information at a glance at all times. |

|

|

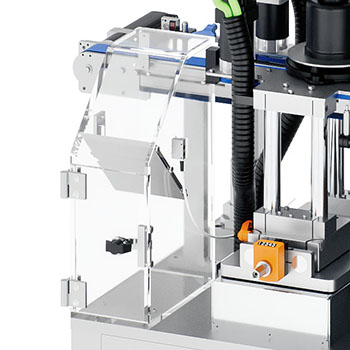

To ensure that products are not passed down the line without labels, a control system for label presence check detects any that are missing. After the checking station, products with a missing label are re-routed to a reject box by compressed air. |

|

|

An optional camera system checks both the presence and the position of labels, and uses the captured data to make adjustments for the next labeling. In case of tolerance deviations, machine parameters are adjusted fully automatically as necessary. This ensures that e. g. round labels are placed exactly in the center of round products. |

|

|

For printing variable data, various hot-foil and thermal transfer printers are easy to integrate. |

|

|

Various interfaces are available for line integration. For the infeed and outfeed of the conveyor belt optionally motorized transfer belts can be supplied, which ensure a smooth transfer of the products from and to other conveyor belts in the line. |

Technical data

|

Labeling type: |

Top labeling |

|

Product specifications: |

Rectangular, cylindrical, free-standing |

|

Product dimensions: |

50 x 50 x 15 mm - 100 x 100 x 150 mm (L x W x H) |

|

Label dimensions: |

15 - 100 mm x 30 - 100 mm (W x L) |

|

Capacity: |

Up to 250 products/minute |

|

Power supply: |

400V, TN-C-S, 50 Hz, 3 phases / 208 V, delta 4-wire, 60 Hz, 3 phases (optional) |

|

Compressed air supply: |

6 bar |

|

Printer: |

Various hot-foil and thermal transfer printers (optional) |

|

Components: |

Control panel with 7 inch touchscreen, signal column, conveyor belt, side guides for products, applicator with digital position indicators for all adjustments, label presence check, product reject station |

|

Options: |

Camera system for checking the label position, self-adjusting system for tracking the label position, print check, code check, transfer belts at the infeed and outfeed end |

|

Note: |

If optional features are chosen, the above data may vary |

Contact

Request for quotation

We produce labeling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labeling solution requirements on the following page so that we can give you a good consultation.